Overview

75-SERIES

Available in five different reach sizes from 5.6m to 8.0m reach sizes and powered by high-performance 70hp hydraulics, McConnel’s new heavy-duty 75 Series features a radical new look and feature set and is aimed at busy professional contractors.

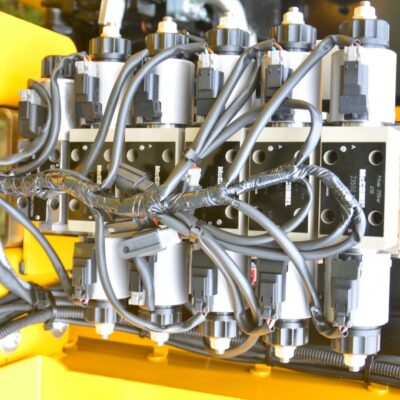

Among the key new features of the machine is an innovative high-efficiency oil tank and cooling system which deliver an outstanding de-aeration performance, produce a very low overall flow velocity, and eliminate areas in the tank where resting oil can concentrate.

Designed to improve efficiency, performance and durability, this new system ensures consistent cooling in all weather conditions and significantly reduces heat build-up.

OVERVIEW

Precision-engineered at McConnel’s Shropshire production facility, 75 Series Power Arms are created from heavy-duty Strenx (Domex) steel, feature tapered C-section arms for extra strength, and meet the UK’s ISO 9001 hallmark of quality management.

A choice of hundreds of different build options enables operators to customise a machine precisely to their individual needs.

Heavy duty build quality

Created from heavy-duty Strenx (Domex) steel, 75 Series machines have tapered seam-welded arms for extra strength

Choice of control systems

Available with a choice of three advanced control options: REVOLUTION, EVOLUTION, and MOTION

Easy Drive System

Automatically adjusts the flailhead position 30 times a second, increasing mowing speeds up to 18 km/h while reducing operator input and fatigue.

What’s new

- Automated hydraulic reversing fan

- Soft-start electric rotor control

- Modern styling with full-width bumper bar

- Easy access cover for maintenance

- Cab protection as standard

- LED road lighting

- Strobe working lights

- Built-in tool box

Key Features

5.6m, 6.4m, 6.5m, 7.7m and 8.0m reach

A choice of three advanced control systems

High-performance 70hp hydraulics

3-point linkage (PA5675, PA6475, PA6575T)

Five-point axle mounting (PA7775T and PA8075T)

Telescopic armset options

Easy Drive System (optional)

Hydraulic Power Slew

Hydraulic safety breakaway

Choice of nine different flailheads

Choice of 14 attachments

Technical Specifications

| Model | PA5675 | PA6475 | PA6575T | PA7775T | PA8075T |

|---|---|---|---|---|---|

| Reach | 5.6m | 6.4m | 6.5m | 7.7m | 8.0m |

| Machine weight* | TBC | TBC | TBC | TBC | TBC |

| Tractor hp requirement | 120hp | 120hp | 120hp | 120hp | 120hp |

| Tractor weight requirement | 5000kg | 5000kg | 5500kg | 5500kg | 5500kg |

Brochure

Find out more about this product by downloading our brochure

Specifications

Revolution Controls

Simple to use, yet highly sophisticated, REVOLUTION blows away outdated and generic control systems – delivering outstanding one-handed control and the best feature set in the industry.

REVOLUTION is a state-of-the-art multi-function reach arm control system that enables users to tackle a huge variety of work tasks; offers huge strides in productivity, safety and reliability; and enables precise fingertip control for outstanding manoeuvrability.

McConnel’s REVOLUTION is the first control package ever developed which gives operators full proportional control of up to eight different functions, as well as two further bang-bang functions. It also comes with McConnel’s acclaimed Easy Drive System, boosting safety and increasing verge-mowing speeds by up to 4.5 times the norm.

INTUITIVE SOFTWARE

McConnel’s design philosophy is to take the complicated and make it simple and nowhere is this more evident than in the brand new software driving the system. Customers can access real-time performance information on everything from power output to warning systems as well as checking service schedules and adjusting control sensitivity settings.

ERGONOMIC JOYSTICK

Developed in-house exclusively for Power Arms, the system allows full proportional control of up to eight different functions from the joystick and full one-handed control of even the most complex operations. Operators now have the choice of a standard REVOLUTION controls joystick or a REVOLUTION MINI controls joystick

FULL COLOUR DISPLAY

The 5.5 inch high-visibility display is the best on the market and is unique for its size and quality. The screen can be mounted around the cab and provides at-a-glance information on active functions, power output, job hours, warning alarms and servicing alerts.

FULLY CUSTOMISABLE CONTROLS

REVOLUTION makes it easy for customers to customise the joystick buttons to a variety of different functions, allowing you to create a configuration for your personal preferences or for a specific task. You can even switch between configurations at the touch of a button – giving you full control.

MCCONNEL’S EASY DRIVE SYSTEM (EDS)

Incorporated into REVOLUTION and allows operators to work up to 4.5 times faster than on machines without it. EDS automatically adjusts the cutting attachment to precisely match the contours of the ground. It also saves fuel consumption by allowing you to work up to three gears higher than rival systems.

McConnel offers the most advanced Power Arm control systems anywhere in the world, delivering the best in fingertip precision, multi-functional proportional control, and simple yet sophisticated software created exclusively, in-house, for McConnel Power Arms. The table below shows the suitability of each control system with each Power Arm series.

| SUITABILITY | |||||

|---|---|---|---|---|---|

| Cable | MOTION Mini | MOTION | EVOLUTION | REVOLUTION (& MINI) | |

| Swingtrim | X | X | |||

| 30-Series | X | X | |||

| 45-Series | X | X | |||

| 55-ECO-Series | X | X | |||

| 55-Series | X | X | X | ||

| 60-Series | X | X | X | X | |

| 65-Series | X | X | X | ||

| 70-Series | X | X | X | ||

| 75-Series | X | X | X | ||

| 85-Series | X | X | X | ||

| VERSI-Series | X | X | X | ||

Evolution Control

OVERVIEW

Created for customers who demand outstanding precision and functionality, EVOLUTION offers eight-function controls; joystick technology pioneered by McConnel’s acclaimed REVOLUTION system; and a robust design capable of withstanding the demands of busy professional contractors.

Five proportional functions* are available for precise fingertip control, while the joystick enables operators to customise the controls to suit their personal preferences or the job at hand.

A new software package developed exclusively for McConnel by industry specialists offers simple yet sophisticated functionality, while the rugged new control pod has an ergonomic key layout which enables fast and intuitive one-handed control.

FEATURES

Proven joystick technology

EVOLUTION features the same proven joystick built into McConnel’s flagship controller REVOLUTION, enabling light and precise fingertip control of complex manoeuvres as well as easy key mapping and bullet-proof build quality.

Advanced Float cruise control

Created as a value-for-money cruise control system, Advanced Float automatically adjusts the height of the flailhead to suit the contours of the ground when used in conjunction with an angle float kit, leaving the operator to regulate only the reach. More effective and flexible than a standard lift float kit, the system thrives on embankments and verges and enhances working speeds, comfort and visibility without the need for resetting.

Benefits

- Advanced new eight-function controller

- Five proportional functions

- Uses acclaimed REVOLUTION joystick technology

- Ergonomic key layout

- Cruise control

- Advanced control-mapping options

- Light intuitive control

- Smooth learning curve

- Complex functionality

- State-of-the-art software package

- Comfortable arm rest available

- Rugged build quality

| SUITABILITY | |||||

|---|---|---|---|---|---|

| Cable | MOTION Mini | MOTION | EVOLUTION | REVOLUTION | |

| Swingtrim | X | X | |||

| 30-Series | X | X | |||

| 45-Series | X | X | |||

| 55 Eco-Series | X | X | |||

| 55-Series | X | X | X | ||

| 60-Series | X | X | X | X | |

| 65-Series | X | X* | X | ||

| 70-Series | X | X | X | ||

| 85-Series | X | X | X | ||

| VERSI-Series | X | X | X | ||

* Please note – Only three proportional functions are available on 65-series Power Arms.

Downloads

Motion Control

OVERVIEW

McConnel’s MOTION control system is an easy-to-master seven-function (six proportional) controller which offers light and precise fingertip control of complex manoeuvres and operations.

Featuring an ergonomic control pod, sophisticated software and a precise ‘short-stick’, the system has been created to be rugged, responsive and reliable.

FEATURES

Purpose-built software

McConnel has teamed up with a leading industry specialist to ensure the best in functionality and performance, creating a new software system that is simple to master yet extremely sophisticated. The system was built exclusively for MOTION and has been designed to deliver intuitive control and a consistent, reliable performance.

Enhanced comfort

MOTION is available with a reinforced polyurethane foam armrest which is not only hard-wearing and durable, but also offers greater comfort.

Benefits

- Up to six proportional functions

- Light, intuitive control,

- Ergonomic short stick for precise fingertip control

- Easy to master

- Complex functionality

- Revamped software

- Comfortable

- Rugged build quality

| SUITABILITY | |||||

|---|---|---|---|---|---|

| Cable | MOTION Mini | MOTION | EVOLUTION | REVOLUTION | |

| Swingtrim | X | X | |||

| 30-Series | X | X | |||

| 45-Series | X | X | |||

| 55 Eco-Series | X | X | |||

| 55-Series | X | X | X | ||

| 60-Series | X | X | X | X | |

| 65-Series | X | X | X | ||

| 70-Series | X | X | X | ||

| 85-Series | X | X | X | ||

| VERSI-Series | X | X | X | ||

Downloads

Omega Flailhead

OVERVIEW

McConnel’s toughest and most powerful flailhead, the Omega has been created for professional green maintenance specialists tackling dense overgrowth and mature hedgerows.

Built around the Omega rotor, which allows heavy-duty flails to spin through 360 degrees to protect the machine from damage, the flailhead can tackle material up to 100mm in thickness

Features

- Three different working widths from 1.2m to 1.6m

- Heavy-duty rotor and flails

- Direct and belt drive options

- Front flap kit

- Rear flap kit

- Wire trap

- Adjustable front hood

- Robust build quality

- HD front flap kit

- Extremely robust construction

MCCONNEL’S OMEGA ROTOR IN ACTION

See McConnel’s Omega rotor in action:

Models

- 1.2m Omega DD

- 1.2m Omega BD

- 1.5m Omega DD

- 1.5m Omega BD

- 1.6m Omega DD

- 1.6m Omega BD

| SUITABILITY | |||

|---|---|---|---|

| Omega 1.2m | Omega 1.5m | Omega 1.6m | |

| Swingtrim | |||

| 30-Series | |||

| 45-Series | |||

| 55 Eco-Series | X | ||

| 55-Series | X | X | |

| 60-Series | X | X | |

| 65-Series | X | X | X |

| 70-Series | X | X | X |

| 85-Series | X | X | X |

| VERSI-Series | X | X | |

Downloads

TwinCut Flailhead

OVERVIEW

Featuring not one but two high-powered spiral rotors, the new Twincut Flailhead has been designed to tackle hedgerows in a single-pass – delivering both a heavy-duty cut and a fine finish in a single operation.

The first rotor is equipped with a heavy-duty T-flail which cuts in a downward direction, reducing the amount of debris blown forward. The material is finely mulched and the bulk is retained in the hedgerow.

The second rotor is set 50mm lower, cuts in an upward direction and is equipped with a fine-cut McConnel competition flail. This combination is perfect for shaping the hedge and leaving behind a precise and attractive finish.

Designed to boost the productivity and efficiency of contractors, Twincut’s unique double cutting action saves time, cuts fuel costs, and increases the amount of work that can be done in a day.

Features

- 1.2m and 1.5m working widths

- Unique design

- No need for a front cover

- Effective single-pass cutting

- Boosts productivity

- Increases working speeds

- Dramatic fuel savings

- Reduces damage to fields with fewer wheel markings

- Unique patented design

- Close-cutting

Models

- 1.2m Twincut DD

- 1.5m Twincut DD

TWINCUT FLAILHEAD IN ACTION

See McConnel’s innovative TwinCut flailhead in action:

| SUITABILITY | ||

|---|---|---|

| 1.2m Twincut | 1.5m Twincut | |

| Swingtrim | ||

| 30-series | ||

| 45-series | ||

| 55 ECO-Series | ||

| 55-series | ||

| 60-series | ||

| 65-Series | X | |

| 70-series | X | |

| 85-series | X | X |

| VERSI-series | ||

* The Twincut Flailhead is not suitable for machines with telescopic arms

Downloads

Multicut Flailhead

OVERVIEW

Ideally suited for professional hedgecutting and verge mowing, this premium range of flailheads is built around the Multicut rotor and features wrap-around lugs which provide excellent strength and protection.

The spiral layout of the lugs ensures that only two flails are cutting at any one time for a smooth, continuous cutting action.

Features

- Four different working widths from 1.2m to 2.0m

- Complete choice of flails

- Direct and belt drive options

- Front flap kit (Heavy duty version available with the 65-series and above)

- Rear flap kit

- Wire trap

- Adjustable front hood

- Optional skid kit

- Inboard and outboard options

- Robust build quality

- Multicut flailheads for 65-series Power Arms and above come with the new F14 T-flail equipped as standard

- Optional cushioned roller *

- Optional hydraulic roller *

- Optional hydraulic hood *

* Not available on the 2.0m model

Models

- 1.2m Multicut DD

- 1.2m Multicut BD

- 1.5m Multicut DD

- 1.5m Multicut BD

- 1.6m Multicut DD

- 1.6m Multicut BD

- 2.0m Multicut DD

- 2.0m Multicut BD

| SUITABILITY | ||||

|---|---|---|---|---|

| Multicut 1.2m | Multicut 1.5m | Multicut 1.6m | Multicut 2.0m | |

| Swingtrim | ||||

| 30-Series | ||||

| 45-Series | ||||

| 55 Eco-Series | X | X | ||

| 55-Series | X | X | ||

| 60-Series | X | X | ||

| 65-Series | X | X | X | |

| 70-Series | X | X | X | |

| 85-Series | X | X | X | X |

| VERSI-Series | X | X | ||

* Multicut 1.6m and 2.0m flailheads not compatible with telescopic-arm machines

Downloads

Rotary Heads

ROTARY HEAD – FINE CUT

1.2m Fine Cut Rotary Head

Fine Cut Rotary Head

Available with a 1.2m working width and a 25mm cutting capacity

Designed to deliver the best in cut quality, McConnel’s 1.2m FineCut Rotary Head is equipped with two high-speed rotors and eight blades, cutting material up to 25mm thick into a fine mulch.

This not only ensures a fine finish, but also retains most of the debris within the hedge for healthy growth and a tidy finish.

Features and benefits

- 1.2m working widths

- 25mm cutting capacity

- Weight: 130kg

- Left or right hand build options

- Twin rotor, eight blade configuration

- 45 ltr/min oil flow

ROTARY HEADS – MD

1.2m Rotary Head MD, 1.5m Rotary Head MD

Rotary Head MD

A choice of 1.2m and 1.5m working width and a cutting capacity of 100mm

McConnel’s range of MD rotary heads delivers a viable alternative to flail cutting, with a choice of two different working widths, blade or chain cutting options, and rugged build quality.

The MD range delivers a fine cut attractive finish and is compatible with most mid-range and top-end Power Arms.

Features and benefits

- 1.2m and 1.5m working widths

- 100mm cutting capacity

- Chain or blade options

- Hydraulic front hood

- Equally adept at cutting grass and hedges

ROTARY HEADS – HD

1.2m Rotary Head HD, 1.5m Rotary Head HD

Rotary Head HD

A choice of 1.2m and 1.5m working widths and a cutting capacity of 120mm

The toughest and most durable Rotary Heads in the McConnel range are built to last with a choice of two different working widths, blade or chain cutting options and a cutting capacity of up to 100mm.

The HD range delivers an attractive finish and is compatible with top-end Power Arms.

Features and benefits

- 1.2m and 1.5m working widths

- Extremely durable

- 120mm cutting capacity

- Chain or blade options

- Hydraulic front hood

- Equally adept at cutting grass and hedges

ROTARY HEAD IN ACTION

See McConnel’s HD Rotary Head attachment in action:

| SUITABILITY | |||

|---|---|---|---|

| Fine Cut Rotary Head | Rotary Head MD | Rotary Head HD | |

| Swingtrim | |||

| 30-Series | X | ||

| 45-Series | X | ||

| 55 Eco-Series | X | X | |

| 55-Series | X | X | |

| 60-Series | X | X | |

| 65-Series | X | X | |

| 70-Series | X | X | |

| 85-Series | X | X | |

| VERSI-Series | |||

* Rotary Heads are not compatible with telescopic arm machines.

** 1.5m HD Rotary Head is not compatible with VFR models

Downloads

Multisaws

MULTISAW COMPACT

Compact 1400, Compact 2100, Compact 2800

A choice of 1.4m, 2.1m and 2.8m models is available, each with a cutting capacity of 80mm.

A robust Multisaw with a choice of three different working widths, the Compact range is designed for use with smaller Power Arms and is ideal for farmers, contractors, amenities specialists, and local government.

Quiet enough to use close to residential areas, the machines can tackle material up to 80mm thick, are equally adept at cutting thin and thick vegetation

Features and benefits

- 1.4m, 2.1m, and 2.8m working widths

- Compact 1400: 4-blade configuration

- Compact 2100: 6-blade configuration

- Compact 2800: 8-blade configuration

- 5mm-80mm cutting capacity

- Trapping protection

- Four-blade configuration

- 350mm blade thickness

- Super-strength tungsten carbide Videa teeth

- Minimum oil flow: 40 ltrs/min

MULTISAW SD

Multisaw 1600

The Multisaw SD has a working width of 1.6m and a cutting capacity of 120mm

A robust and powerful four-blade Multisaw with a 1.6m working widths, the SD Multisaw is designed for use with smaller Power Arms and is ideal for farmers, contractors, amenities specialists, and local government.

Quiet enough to use close to residential areas, the machine can tackle material up to 120mm thick and is equally adept at cutting bushes and branches.

Features and benefits

- 1.6m working width

- 5mm-120mm cutting capacity

- Four-blade configuration

- 400mm blade thickness

- Super-strength tungsten carbide Videa teeth

- Minimum oil flow: 50 ltrs/min

MULTISAW HD

Multisaw 2100, 2400

The 2.0m HD Multi saw is available with a 150mm cutting capacity. The 2.4m model has a 200mm cutting capacity

McConnel’s most powerful Multisaws, the HD range offers heavy-duty build quality, working widths up to 2.4m,and a ferocious cutting action capable of tackling material up to 200mm (HD 2400).

Designed for larger Power Arms, the HD range is ideal for farmers, forestry teams, local government, and contractors looking to expand the services they offer.

Features and benefits

- 2.0m, and 2.4m working widths

- 5mm-100mm cutting capacity

- Four-blade configuration

- 500mm blade thickness (HD2000)

- 600mm blade thickness (HD2400)

- Super-strength tungsten carbide Videa teeth

- Minimum oil flow: 50/85 ltrs/min

- Weight: 220kg (HD 2000)

- Weight: 280kg (HD2400)

| SUITABILITY | |||

|---|---|---|---|

| Multisaw Compact | Multisaw SD | Multisaw HD | |

| Swingtrim | X | ||

| 30-Series | X | X | |

| 45-Series | X | X | |

| 55 Eco-Series | |||

| 55-Series | X | ||

| 60-Series | X | ||

| 65-Series | X | ||

| 70-Series | X | ||

| 85-Series | X | ||

| VERSI-Series | X | X | X |

Downloads

Cutterbars

SWINGTRIM CUTTERBARS

Available in 1.2m and 1.5m working widths, the Swingtrim Cutterbar delivers a maximum cutting capacity of 20mm

Created exclusively for the Swingtrim, these specialist cutterbars are light and manoeuvrable.

The cutterbars can be rotated through 270 degrees for the best in cutting flexibility.

Features and benefits

- 20mm cutting capacity

- 1.2m and 1.5m working widths

- Weight: 40kg

- Hard-wearing Carbodux teeth

- Exceptional manoeuvrability

CUTTERBARS SD

MHL150, MHL180, MHL210

Three different working widths are available: 1.5m, 1.8m, and 2.1m with a cutting capacity of 30mm

High-performance cutterbars designed for the regular trimming of hedges and bushes.

McConnel’s SD machines are equipped with special serrated teeth which deliver a fine-cut finish and can tackle material up to 30mm.

Features and benefits

- Choice of 1.5m, 1.8m, and 2.1m working widths

- 30mm cutting capacity

- Minimum oil flow: 16-32 ltrs/min

- 200-400 cuts per minute

- Hard-wearing teeth

- Fingers armed with rounded ends prevent trapping of material

- Easy to replace blades

- Weight: 60-68kg

CUTTERBARS MD

MHS200

A medium-duty cutter bar with a 2.0m working width, the MD Cutterbar has a cutting capacity of 45mm.

A powerful cutterbar designed for maintaining trees, bushes and hedges.

The MD edition is tough and durable and its tungsten-carbide teeth can tackle material up to 45mm thick.

Features and benefits

- 2.0m working width

- 45mm cutting capacity

- 60 cuts per minute

- Minimum oil flow: 45 ltrs/min

- Hardwearing teeth

- Weight: 130kg

- Robust build quality

CUTTERBARS HD

MHX170, MHX230, MHS270

Available in a choice of 1.7m, 2.3m and 2.7m working widths, the HD Cutterbars have a 110mm cutting capacity.

Powerful heavy-duty cutterbars that can tackle material up to 110mm thick.

The HD range is extremely robust and can be used to tackle hedges, bushes, and can even prune trees.

Features and benefits

- 1.7m, 2.3m and 2.7m working widths

- 110mm cutting capacity

- 60 cuts per minute

- Minimum oil flow: 45 ltrs/min

- Hardox steel trimmer bars for exceptional durability

- Hydraulic flow divider

- Soft-turn technology

- Weight: 170-250kg

| SUITABILITY | ||||

|---|---|---|---|---|

| Swingtrim Cutterbar | Cutterbar SD | Cutterbar MD | Cutterbar HD | |

| Swingtrim | X | |||

| 30-Series | X | |||

| 45-Series | X | X | X | |

| 55 Eco-Series | X | X | X | |

| 55-Series | X | X | X | |

| 60-Series | X | X | X | |

| 65-Series | X | X | X | |

| 70-Series | X | X | X | |

| 85-Series | X | X | X | |

| VERSI-Series | X | X | X | |

Downloads

Ditch & Grip Cleaner

OVERVIEW

The perfect tool for removing silt and mud from drainage ditches, this heavy duty attachment is compatible with Power Arms from the 55-series and upwards. It has also be successfully adapted to work with a JCB.

Features and benefits

- 600mm diameter rotary head

- Four cutting blades

- Four throwing blades

- Choice of blades

- Boron steel construction

- Choice of hydraulically operated 0-70 degree or 0-120 degree head rotation

- Ideal for roadside grip clearing

- Adjustable exit spout

- Heavy-duty construction

- Manual or hydraulic chute rotation available

- Weight: 323kg

DITCH AND GRIP CLEANER IN ACTION

See McConnel’s Ditch and Grip cleaner attachment in action:

| SUITABILITY | |

|---|---|

| Ditch Cleaner | |

| Swingtrim | |

| 30-Series | |

| 45-Series | |

| 55 Eco-Series | X |

| 55-Series | X |

| 60-Series | X |

| 65-Series | X |

| 70-Series | X |

| 85-Series | X |

| VERSI-Series | X |

Downloads

Optional Accessories

OVERVIEW

McConnel offers customers a comprehensive range of general accessories – boosting performance, manoeuvrability, safety and functionality, including:

Lift and Angle Float kits

The Lift Float Kit enables the cutting attachment to automatically follow the contours of the ground in a vertical plane, while the Angle Float Kit works in a horizontal plane.

Reducing fatigue by lowering the amount of operator input required, the float kits also increase accuracy, prevent scalping, and boost durability by eliminating excessive wear and tear.

Oil Cooler kit

Improves the performance of Power Arms and prolongs oil life – even in the most arduous conditions.

Safety equipment

McConnel offers road lighting kits, magnetic warning arrows, and window guards, protecting operators and the safety of the public.

Flailhead options

McConnel offers a number of enhancements for flailheads including: Front flap kits, hydraulic rollers, skid kits, and a cushioned grass mowing roller.

Debris Blower

Keeps pavements and roads clear after cutting.

Front Mounting Kit

Enables operators to transform their Power Arm into a front-mount model for enhanced visibility

Telescopic Dipper Arm

OVERVIEW

McConnel’s telescopic dipper arms provide between 1.0m and 1.5m extension (dependent on the model), providing extra reach on demand while protecting maneouvrability by enabling the arm to be retratcted in confined environments.

Features and benefits

- Extra reach on demand

- Compact arm geometry

- Operated via in-cab controls

- Simple, robust design

- Improves the cutting range

- Ideal when working in narrow lanes

| SUITABILITY | |

|---|---|

| Telescopic arms | |

| Swingtrim | |

| 30-Series | |

| 45-Series | |

| 55 Eco-Series | |

| 55-Series | |

| 60-Series | |

| 65-Series | X |

| 70-Series | X |

| 85-Series | X |

| VERSI-Series | |

Downloads

Telescopic VFR

OVERVIEW

A major advance in comfort, precision and safety, Telescopic-Variable Forward Reach (Tele-VFR) enables operators to position the flailhead in front of the cab boosting visibility and reducing user fatigue.

The new armset takes the comfort and control offered by McConnel’s proven VFR technology and combines these qualities with the versatility of a telescopic extension, which can also be retracted for added manoeuvrability when working in confined spaces.

Customer experience

Irish contractor Thomas Moloney, who was one of the first customers to purchase a Tele-VFR machine, explained the benefits of the new technology, saying: “Modern tractor designs position the cab further forward which is great for most jobs but is far from ideal when cutting grass or hedges because you’re constantly looking over your shoulder and twisting around, which can put strain on operators.

“The beauty of this machine is that it is much more comfortable to operate when working for long periods, and because the visibility is better, it also improves precision and safety.

“The arm is always precisely where I need it, which makes it intuitive to control and increases the speed at which you can work. It’s also very stable and well-balanced.”

Enhanced safety

Tele-VFR

Created following feedback from professional and specialist contractors, the new armset is available on new 6.5m, 7.2m and 8.0m 85-series machines.

Conventional arms extend behind the cab resulting in operators having to make a series of visual adjustments from front to rear as the operator checks the road ahead, then breaks off to check the performance of the flailhead.

TELE-VFR takes full advantage of the 120-degree focal range of the human eye, allowing operators to flick simultaneously back and forth from the road to the flailhead’s position alongside the cab without compromising safety.

Improved productivity

Conventional reach arms are not designed for cutting around obstacles such as road signs, trees, and therefore struggle to make a tidy cut without being forced into a series of time-consuming and potentially hazardous manoeuvres.

By enabling an extended forward reach of up to 2.39m, TELE-VFR offers over 400% increase in the size of the cutting area, boosting efficiency and productivity and enabling the arm to cut behind obstacles.

Benefits

- Improves safety by allowing the operator to concentrate on the road ahead

- Enables operators to set the arm position according to the task or personal preference

- Enhances comfort

- Ideal for both hedge cutting and verge mowing

- Cutting position is adjustable from the cab at the touch of a button

- Telescopic arm allows close-in cutting, while delivering extra reach on demand

- Flexible positioning for cutting around obstacles

- Intuitive controls

| SUITABILITY | |

|---|---|

| Tele-VFR | |

| Swingtrim | |

| 30-Series | |

| 45-Series | |

| 55 Eco-Series | |

| 55-Series | |

| 60-Series | |

| 65-Series | |

| 70-Series | |

| 85-Series | X |

| VERSI-Series | |

Downloads

Variable Forward Reach

OVERVIEW

McConnel’s Variable Forward Reach (VFR) armset enables operators to adjust the position of the cutting head alongside the tractor for improved comfort, visibility and safety.

Ideal for both verge-mowing and hedge-cutting, the system is extremely versatile and enables cutting anywhere along an adjustable cutting range from fully forward to behind the tractor.

The technology improves safety by allowing the operator to concentrate on the road ahead; enables operators to set the arm position according to the task or personal preference; and delivers flexible positioning for cutting around obstacles.

Features and benefits

- Improves comfort and visibility

- Reduces fatigue

- Positioning can be tailored to the job or personal preference

- Boosts safety by allowing operators to concentrate on the road ahead

- Enables operators to monitor the cutting attachment

- Ideal for working around street furniture

- Thrives in narrow lanes

VARIABLE FORWARD REACH IN ACTION

See McConnel’s Variable Forward reach armset in action hedge cutting:

| SUITABILITY | |

|---|---|

| Tele-VFR | |

| Swingtrim | |

| 30-Series | |

| 45-Series | |

| 55 Eco-Series | |

| 55-Series | |

| 60-Series | X |

| 65-Series | X |

| 70-Series | X |

| 85-Series | X |

| VERSI-Series | |

Downloads

Easy Drive System

OVERVIEW

An innovative hands-free cruise control verge mowing system that increases working speeds from 4km/h up to 18km/h, McConnel’s award-winning Easy Drive System (EDS) delivers greater productivity, reduces fatigue and boosts safety.

Sensors read the contours of the ground ahead, reacting up to 30 times a second to changing conditions and enabling the system to automatically adjust the position of the flailhead. This significantly reduces the amount of driver input required and aids comfort and accuracy.

EDS is an essential tool for verge and highway mowing contractors, allowing operators to work harder, smarter and faster.

EASY DRIVE SYSTEM IN ACTION

McConnel’s award-winning Easy Drive System in action:

Features and benefits

- Winner of the Queen’s Award for Innovation

- Most popular cruise control mowing system on the market

- Increases working speeds by 4.5 times the norm

- Greater accuracy

- Reduced fatigue

- Allows operators to concentrate on the road ahead

- Improves safety

- Responsive technology with 30 adjustments per second

- No additional pivots, bushes, linkages, springs or weights necessary

- Packaged with REVOLUTION, the world’s most advanced Power Arm control system

| SUITABILITY | |

|---|---|

| EDS | |

| Swingtrim | |

| 30-Series | |

| 45-Series | |

| 55 Eco-Series | |

| 55-Series | |

| 60-Series | X |

| 65-Series | X |

| 70-Series | X |

| 85-Series | X |

| VERSI-Series* | X |

* Dependent on machine

Downloads